Recology: A World Without Waste

Waste zero is more than just a goal for the communities in which we work – it’s a goal for ourselves; especially in how we work and with whom we partner. Recology has taken significant measures as a company to work toward waste zero. Want to get there with us? See how we’re changing our behavior, and reach out to schedule a waste audit. Let’s get there together.

How We Work to Achieve Waste Zero

- Recycled Materials

- Efficient Appliances

- Renewable Energy

- Recycling & Composting Systems

- Clean Commuting

Partnering with Communities

Recology sees communities as partners. If we don’t work together to determine how to reach waste zero, it simply won’t work.

Every community is unique and faces different challenges when it comes to recycling, compost, and landfill collection. We understand these nuances, so after conducting a thorough waste audit to better understand existing recycling programs, we work with businesses and communities to identify areas for improvement. Our partnerships with municipalities and commercial customers have yielded some of the industry’s greatest diversion successes.

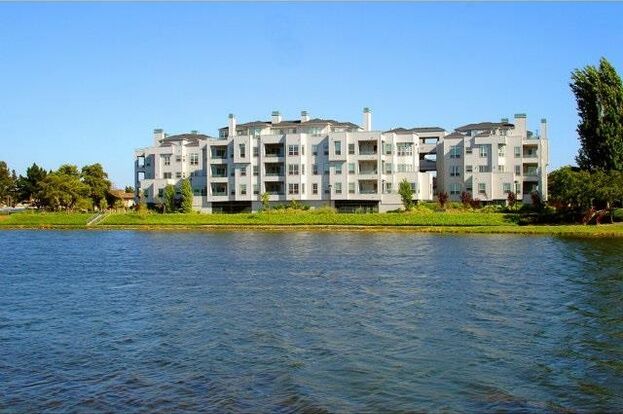

A Case Study with Promontory Point

Apartment Complex

Foster City, CA

WHAT: A multi-family dwelling with 90 units, totaling three separate buildings

WASTE AUDIT RESULTS: Recology found that 30% of residents’ organic waste was being placed in landfill carts.

RECOMMENDATION: Implement and increase organics services, and decrease garbage service. This means providing more green bins and decreasing the number of black bins.

RESULT: Landfill service decrease from 60% to 38%, along with their bill!

2012 Diversion rate: 40%

2016 Diversion rate: 62%